Blog

“Overhang is crucial for shorter stack lengths & low voltage motors“

Objective:

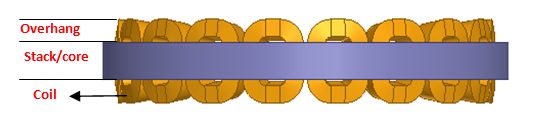

Since low voltage motors (12 volts to 24 volts) must have extremely low resistance to meet performance requirements, the overhang coil that formed during coil preparation has a disadvantage for the efficiency of the motor. Here, we have captured the key parameters and effects.

Effects 1: Extra resistance

There is no way to completely remove a motor’s overhang, however manufacturers often choose to liberal overhangs to speed up production and reduce costs. Some slot and pole combinations, required a specific coil pitch such as 1-2nd, 1-3rd, and 1-4th slots, etc..,

If Slots – pole combinations expecting concentrated winding (1-2nd), its good practice to take this benefits to reduce the overhang but If the slots-pole combinations anticipate distributed winding (1-3rd, etc.), use a molded slot liner, powder coat, or epoxy to effectively reduce the overhang.

In order to enter the coil easily, manual coil preparation requires additional room, which further increases the overhang.

“The length of one side overhang exceeding the stack length is a hint that a compromise was made in the optimizing design for smaller stack lengths”

Effects 2: Drastically reduction in stall torque & peak Torque

Stall torque, which is the torque at closer to zero speed, according to Ohm’s law, the stall torque increases with increasing current and decreasing resistance. (Torque α current)

Solution:

Increased resistance brought on by additional overhang lowers the stall torque and restricts motor current, especially when temperatures are high.

Focus on the resistance for stall torque and working flux density for peak torque if the torque demands higher.

“Steel may be saturated if the torque constant at peak torque graph is drastically reducing means.”

Effects 3: Increase in temperature, dimensions and weight of the motor

The motor’s size and weight will rise further due to the additional overhang and resistance’s effects on temperature due to copper losses (I2R).

Solutions: Put encapsulation in addition to solution 1 to further dissipate the heat.

“Using Motor Constant is the best method to determine a best motor & temperature rise.”